Wire Wrapping vs. Soldering: Which Technique is Right for You?

Wire Wrapping vs. Soldering: Which Technique is Right for You?

Choosing between wire wrapping and soldering is one of the most fundamental decisions in jewelry making. Both techniques create beautiful pieces, but they differ significantly in materials, tools, and outcomes. As a professional jeweler with over a decade of experience, I’ll break down the pros and cons of each method to help you select the right approach for your projects.

Wire Wrapping: The Art of Cold Connections

Wire wrapping involves manipulating metal wire to secure stones and create connections without heat. This ancient technique dates back over 2,000 years to Egyptian and Celtic jewelry traditions.

Pros:

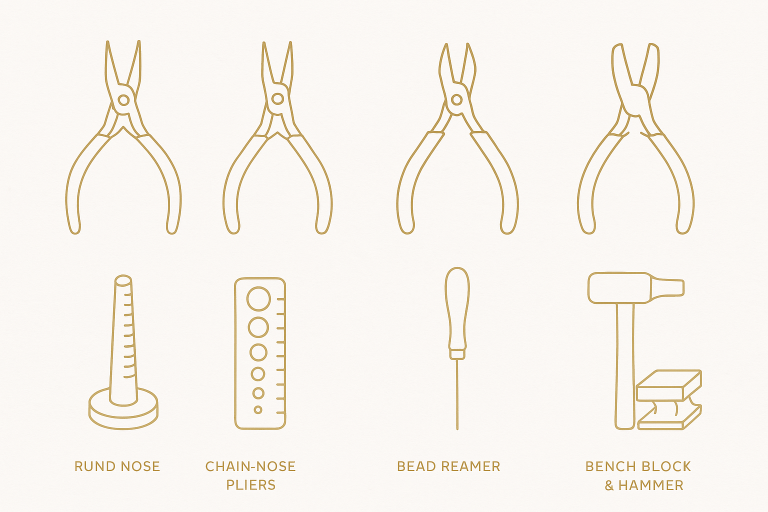

- ✅ Low Cost: Basic tools under $50 (pliers, cutters)

- ✅ Beginner-Friendly: Easier to learn without fire hazards

- ✅ Portable: Create jewelry anywhere with minimal tools

- ✅ Forgiving: Mistakes are easily undone

Cons:

- ❌ Durability Limits: Prone to bending under pressure

- ❌ Size Constraints: Not ideal for large/heavy pieces

- ❌ Time-Consuming: Complex wraps take hours

Ideal Projects:

- Pendants with irregular stones

- Beaded link chains

- Adjustable rings

- Earrings with dangles

Soldering: Precision Metal Joining

Soldering uses high heat (600-1500°F) and filler metal to create permanent bonds between metal components. This technique became popular during the Industrial Revolution for mass production.

Pros:

- ✅ Industrial Strength: Creates permanent bonds

- ✅ Clean Aesthetics: Nearly invisible seams

- ✅ Versatility: Works with all metals and sizes

- ✅ Efficiency: Faster production for multiples

Cons:

- ❌ Steep Learning Curve: Requires torch control skills

- ❌ Higher Investment: Torch setup costs $200-$500+

- ❌ Safety Risks: Open flame and toxic fumes

- ❌ Permanent: Mistakes often ruin pieces

Ideal Projects:

- Wedding bands and permanent rings

- Stone settings with prongs

- Heavy statement necklaces

- Metal components requiring seamless joins

Head-to-Head Comparison

| Factor | Wire Wrapping | Soldering |

|---|---|---|

| Startup Cost | $20-$100 | $200-$800 |

| Learning Time | 1-4 weeks | 3-12 months |

| Durability | Medium (adjustable) | High (permanent) |

| Best for Stones | Raw, irregular shapes | Faceted, calibrated gems |

| Portability | High (travel-friendly) | Low (stationary setup) |

Which Should You Choose?

Choose wire wrapping if: You’re a beginner, work with natural stones, enjoy organic designs, or need a portable craft. This method offers artistic freedom with minimal investment.

Choose soldering if: You create heirloom pieces, work with precious metals, need industrial-strength joins, or produce multiples of the same design. The precision justifies the learning curve.

Many jewelers (myself included) master both techniques – using wire wrapping for artistic expression and soldering for structural integrity. Start with wire wrapping to build fundamental skills, then progress to soldering when your designs demand permanent connections.